Top Aluminum Extruded Heatsink Manufacturer

Wonder has been engaged in the R&D and production of CPU heat sinks and radiators for more than ten years, providing a complete set of research, development, production, sales and service. The designed and developed heat sinks and cooler cover big data systems, refrigeration equipment integrated electronic equipment, LED Lighting, communications and new energy power applications and other fields. At present, the company has passed six utility model patents and two invention patents, and more than ten patents are still pending; The cooling solution providers certified by well-known companies such as Electronics, Lite-On Electronics, and Xunqiang Electronics are important members of the cooling ecosystem in the industry, and have accumulated their own brand awareness in the domestic and international markets.

The Application Of Extruded Heatsink

- Computer PC Servers

- 5G Communications

- Base Stations

- UPS

- Charging Piles

- Machinery

- Automobiles

- Wind Power Generation

- Construction Machinery

- Air Compressors

- Railway Locomotives

- Lamps And LED Lights

- Household Electrical Appliances And Other Industries

The Case Studies Of Extruded Heatsink

Our value is using faster time to fabricating the customer’s product, and help them to forward the product into market, This is also our target. Our advantage is one-stop shop service and faster manufacture time

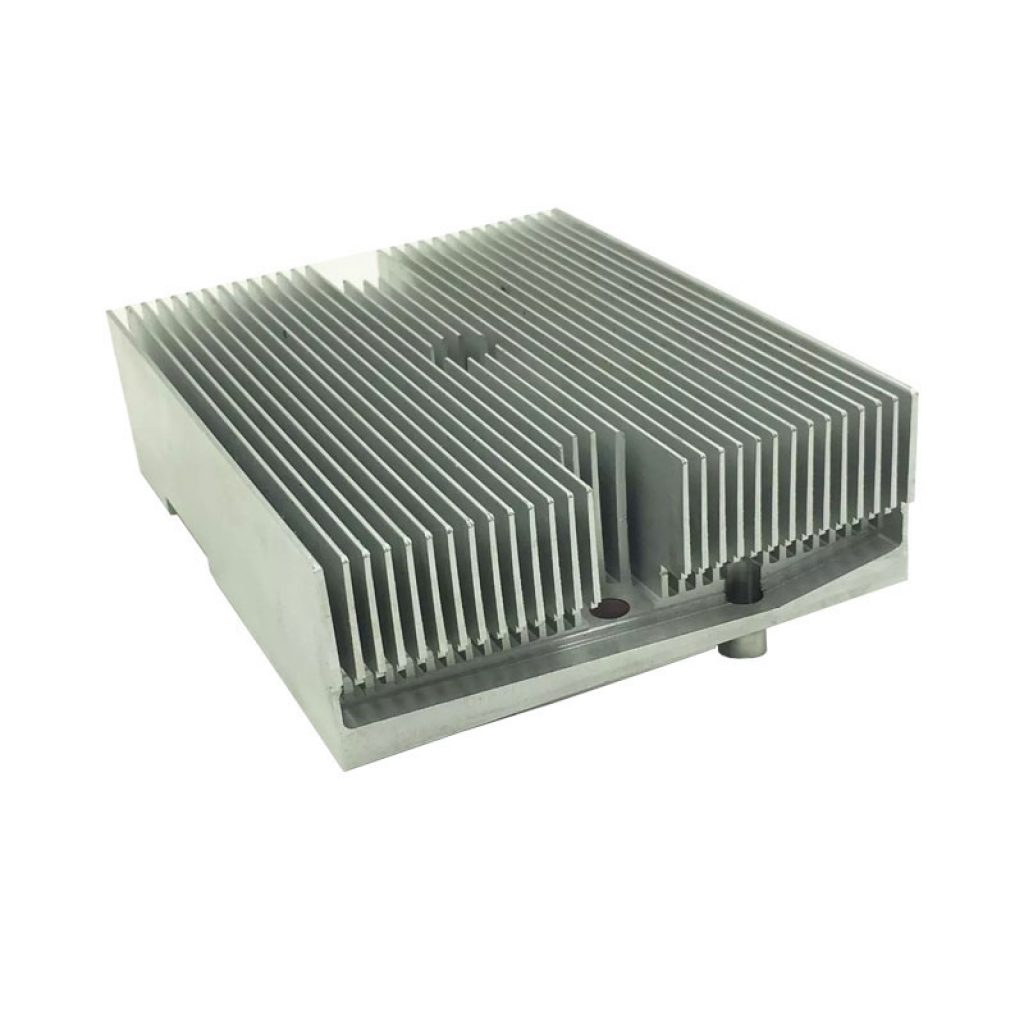

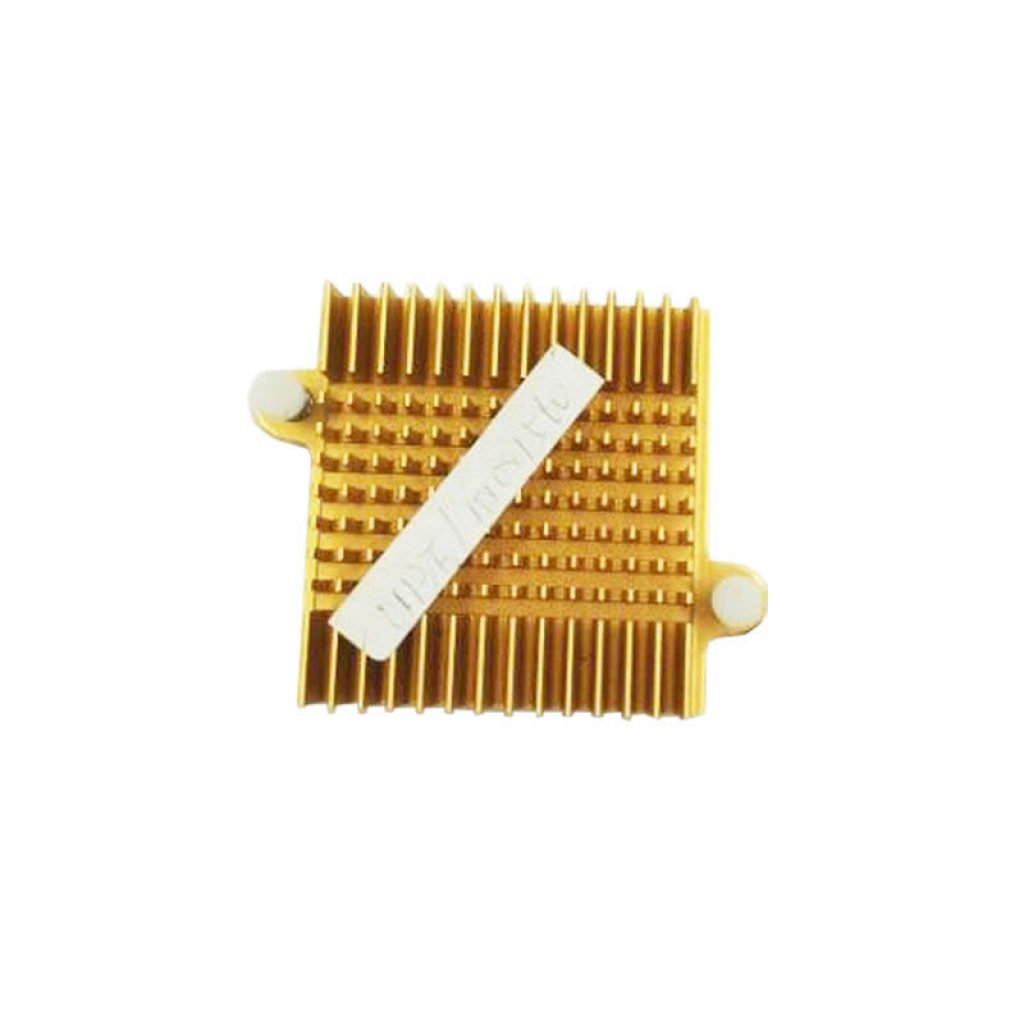

5G chip heat sink

5G communication signal tower custom heat sink

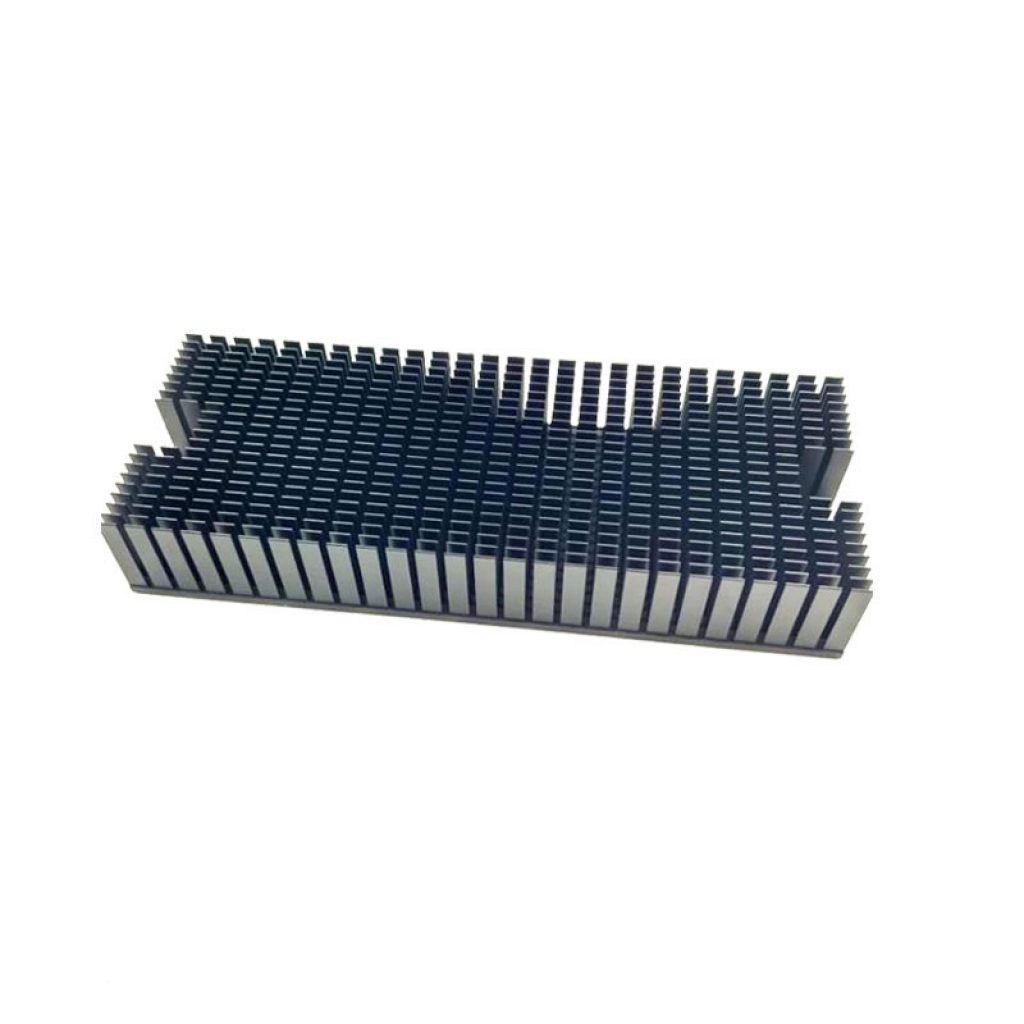

Aluminum extrusion heat sink design

Aluminum extrusion radiator for communication equipment

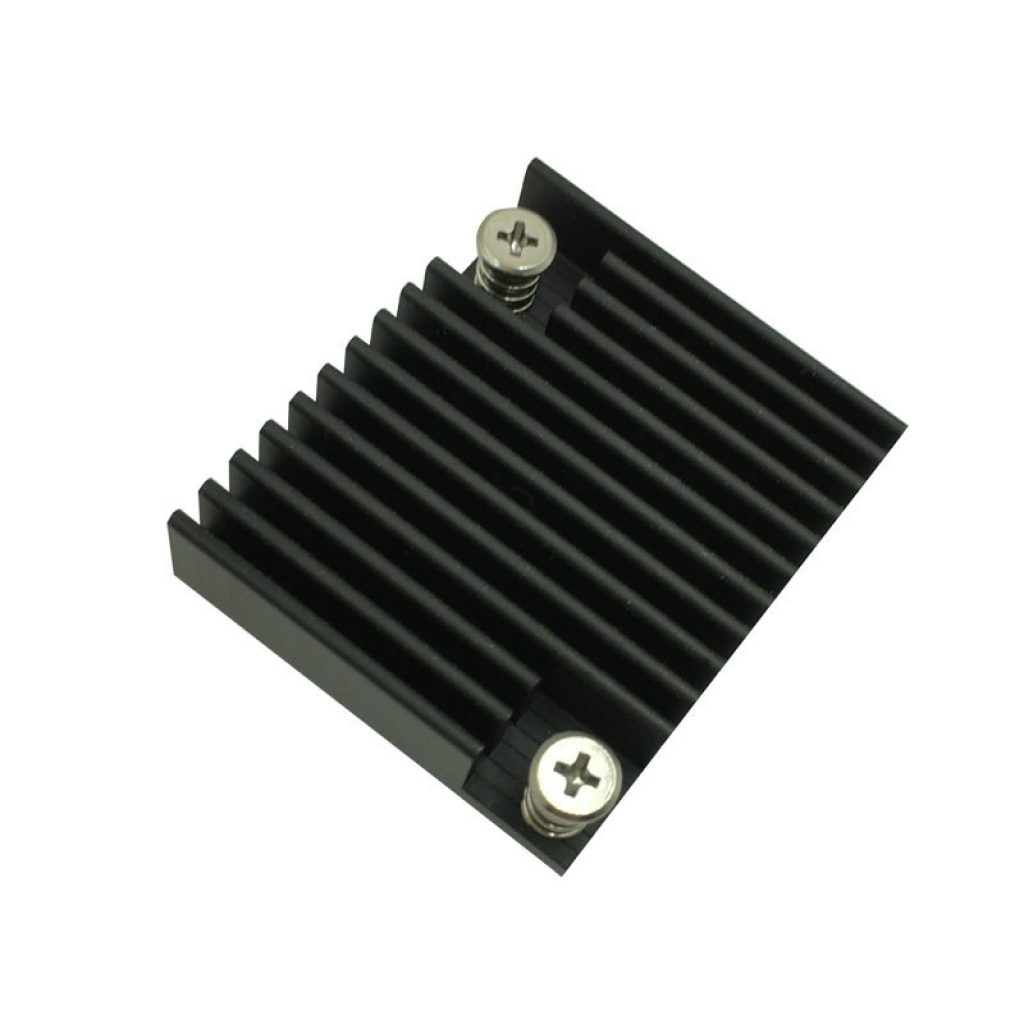

Black heat sink

Charging pile radiator

Computer motherboard chip radiator

Industrial controller cooling shell

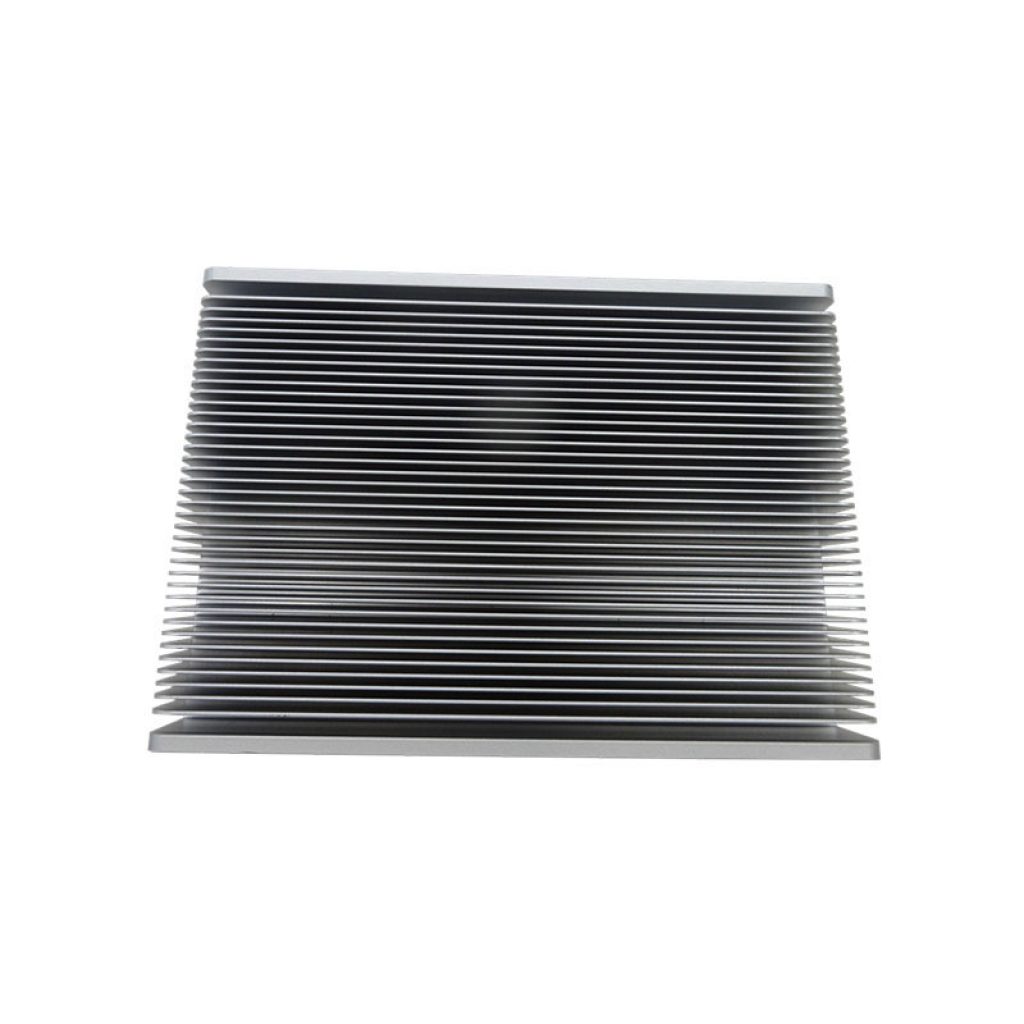

Profile heat sink

Round aluminum extrusion radiator

Sunflower heat sink

UPS custom radiator

What Is Extruded Heatsink?

Profile heat sinks has the characteristics of good heat dissipation performance and good energy saving effect, and is one of the widely used heat sinks types on the market.Extrusion, especially cold extrusion, has high material utilization rate, improved material organization and mechanical properties, simple operation and high productivity. The blank placed in the die is pressurized with a punch or punch to make it plastic.

A pressure processing method for obtaining parts corresponding to the shape of the mold hole or the concave and convex mold. When extruding, the billet produces three-way compressive stress. Even the billet with low plasticity can be extruded and formed. It can be used to make long rod, deep hole, thin wall and special-shaped section parts, which is an important less cutting process. Extrusion is mainly used for the forming of metals, and can also be used for the forming of non-metals such as plastic, rubber, graphite and clay blanks. In the 17th century, the French used a manual screw press to extrude lead pipes for use as water pipes, which was the beginning of cold extrusion.

The cold extrusion of zinc, copper and copper alloys was realized at the end of the 19th century and expanded to the extrusion of aluminum and aluminum alloys in the early 20th century. In the 1930s, the Germans invented phosphating and saponification surface anti-friction lubrication treatment technology, which made the cold extrusion of steel successful, and was initially used to extrude steel bullet casings.

After the Second World War, the cold extrusion of steel was extended to other countries and the scope of application was expanded. In the 1950s, the molten glass lubrication method was used, and the hot extrusion of steel was applied and developed in the metallurgical and mechanical industries.At present, the types of aluminum profile heat sinks commonly used in China are: 5G communication, UPS, charging piles, electronic appliances, aluminum profile radiators for computer service areas, sunflower aluminum profile radiators, profile radiators for power semiconductors, shovel fins, LEDs Lamp radiator, etc.